As retailers prepare for the Black Friday, Cyber Monday, and Christmas rush, retail logistics experts from Advanced Supply Chain (ASC) and ReBound Returns outline strategies to overcome this year’s peak pressure points.

1) Sales surges

In recent years, retailers have successfully extended Black Friday from a one-day spike into a month of promotions. That’s helped secure sales earlier in November and smooth the intense one-day/weekend sales spike.

However, consumer behaviour may be changing. Industry data suggests buyers are now waiting for the core Black Friday, Cyber Monday (BFCM) weekend to secure the best deals (Cyber Monday sales reached £3.3bn last year). In a volatile economy, could this trend of holding out for maximum discounts challenge retailers’ peak season strategies?

“Lingering consumer concerns about job security, rising taxes, energy costs and inflation can make shoppers extremely price sensitive,” says Stuart Greenfield, European Sales Director at ASC. “People will be seeking best value prices and are likely to hang tight.

“This creates a challenge around rapid and efficient replenishment of stock inventory. Black Friday spikes can deplete stock levels overnight, which must be remedied within 48 hours to ensure there’s sufficient stock to satisfy a secondary spike on Cyber Monday. Dealing with this rapid turnaround of inventory could be even more difficult this year, because retailers have diversified and expanded supplier networks to manage the impacts of rising supply chain costs.

“Retailers are consequently receiving goods from many different suppliers around the globe, in varying packaging and labelling formats. Consistency is low and compliance with retailers’ supplier manuals few and far between. Inbound goods need reworking so they are compatible with retailers’ systems and brands, which eats up precious time.

“Automated and digitalised systems can help solve these problems. For example, mobile kiosks in warehouses can standardise and streamline packaging and labelling formats, driving retailer compliance and avoiding order rejections and time spent fixing errors. Kiosks can be connected to transport management systems, helping optimise fleet scheduling, so inbound vehicles arrive at warehouses at the right time. This supports efficient Just In Time inventory and can avoid a risk of vehicles wasting time, queuing for loading bays during the time-critical BFCM weekend.”

2) The Returns Rush

Sales spikes often cause returns spikes. “Deep discounts, seasonal holiday purchases and gifting can encourage impulse purchasing and a general trend of bigger baskets during peak,” said Cristina Parlogea ‑ Cirstea, Customer Success Manager at ReBound Returns.

“Shoppers will generally purchase more than usual to take advantage of flash promotions and have a choice of outfits for festive occasions, as well as checking out possible Christmas gift options. Not all purchases will be kept, and retailers face the challenge of processing higher volumes of returns in short timeframes.

“Goods coming back into warehouses and fulfilment centres need sorting quickly both to get products back into the sales cycle to meet increased customer demand and also to deliver a positive customer experience through quick refunds. ASC and ReBound data shows two-thirds of shoppers will spend again after making a return, as long as they are refunded with two – three days of sending an item back.

“Returns management systems must be based on clearly defined grading processes, so that quick and effective decisions can be made about the quality of returned items. Product inspections can be streamlined to ensure goods are quickly diverted to the most appropriate next stage, whether that’s cleaning, repair, or repackaging – meaning quality control is confidently completed and a swift customer refund can be authorised.

“Effective grading of returns can also provide retailers with valuable data and insight, which can be used to further optimise returns processes to manage costs, save time and enhance customer satisfaction.”

3) Flexing peak policies

Many retailers are also contending with adapting their returns policies to make these more shopper friendly, with extra time allowed for customers to keep or return items seeing returns windows extended from a standard 28-days up to 60-days or more.

Cristina Parlogea ‑ Cirstea, Customer Success Manager at ReBound Returns, explains: “Peak is an opportunity for retailers to attract new customers and build brand loyalty that drives repeat purchasing long after the Christmas decorations come down. Therefore, it’s vital that shoppers are kept happy and returns is seen as a game changer for this.

“Shoppers will snap up BFCM deals to save money on gifts but know there’s a possibility that purchases may have to be changed in the New Year. Giving consumers the ability to do this allows them to confidently shop during popular sales events.

“These policy changes can bring certain operational challenges, such as higher return volumes during January and even into February. This can cause warehouse congestion and delayed stock reintegration, risking issues of product availability and leftover seasonal stock.

“Preparation is key. It’s important to share information returns and logistics partners and about upcoming major sales events and specific price promotions to prepare detailed forecasts. Capacity and inventory can then be better planned, with returns levels and timings anticipated to effectively handle the movement of items being sent back.

“Ultimately, the key to managing extended return windows effectively lies in proactive planning, transparent communication, and close collaboration. These are all factors that can enable retailers to balance consumer friendly returns policies with operational requirements.”

Click here to find out more about how to improve efficiencies in retail logistics, or email: enquiries@advancedsupplychain.com / https://www.advancedsupplychain.com

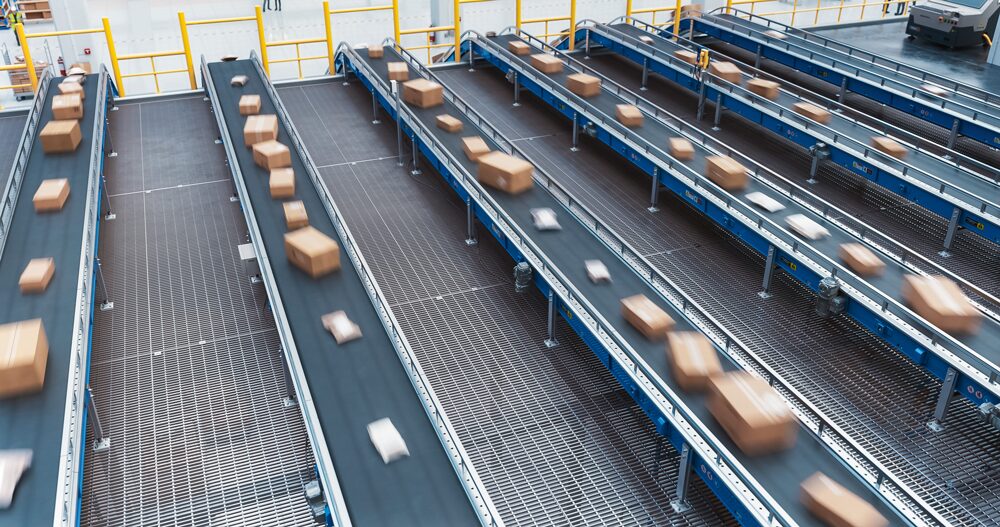

Image courtesy of Shutterstock. Supplied by ASC.